Motosurf on Pipeline & Waimea: Herbie Fletcher & Gerry Lopez

Big thanks to Volcom for sharing this with us!

Recovery team at World Finals

With this year’s world finals around the corner, we found this little clip of K38’s Shawn Alladio helping a downed rider in the middle of the race and later diving to be able to retrieve the racers lost hood. An interesting perspective for sure!

Impellers Back In Stock!

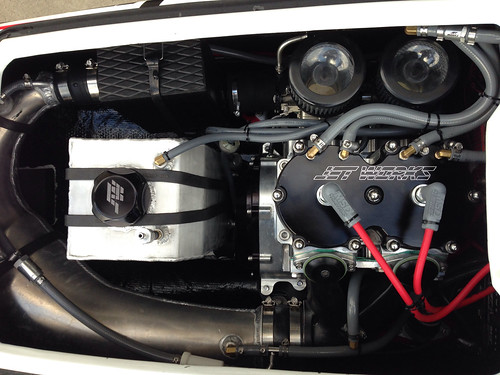

Jetworks 1100cc & 1200cc Monsters

Hook It Up.

Another 1200cc out the door!

Rickter FR2 Evo Now Available

Available as a hull or complete ski with the set up of your choice.

The new Rickter FR2 EVO1 as ridden in the video by Rickter Sponsored Rider Pierre Maxient, as well as Rickter sponsored rider Taylor Curtis. Designed for Motosurf/Freeride and as the most versatile hull for the recreational rider market.

Contact for more information.

Jetworks Water Restrictors

Updated For 2013 is Jetworks 3/8’s Water Restrictor Kit. Replaces QD-38

Now made of 6061 aluminum and anodized for corrosion protection our kit comes with a 2,3, and 4mm polyethylene restrictors and hose clamps. No tool required for adjustments, simply turn the center section by hand to swap the restrictors of your choice restrictor. Perfect for fine tuning water flow and pressure through engines and exhaust systems and for controlling performance and engine temperatures.

Very valuable in cold water riding.

Buy yours here Jetworks Water Restrictor

Flow Control Valve now In Silver

All new flow valves as of new come in polished clear anodize to match you new billet cylinder and exhaust systems.

Read below for an article extract from a 1998 issue of Jet Sport Magazine

“Many racers who bought this product want to keep it a secret … but now Art Gomez of Jetworks Performance give you the behind?the?scenes scoop on this performance device: flow control valves.

The Jetworks Flow Control Valve is for all personal watercraft that have aftermarket pipes. What the valve does is stop the water flowing at idle and off idle speeds into the stinger where it builds up in the waterbox and exhaust hoses. Normally this water has to be forced out upon sudden acceleration in order to get full exhaust flow.

Here’s how it works: At lower speeds, the water pressure in the water lines is low and the valve stops the flow to the stinger and raises the line pressure slightly. This improves response off the line and out of turns. At higher speeds, the water pressure rises and opens the valve to the stinger, allowing unrestricted flow of water. This creates a wall stream of water inside the stinger, thereby increasing the reflectability of the pipe in a similar way like a smaller diameter outlet would do.

What we mean by reflectability, by the way, is how the sonic wave is returned to the exhaust port with more energy, energy that would have escaped through the outlet. What’s nice about the water stream is that it’s variable; as the back pressure increases, it will push the water aside.

This is one reason why some race teams are actually drilling, tapping, and installing a fitting onto the stinger on models not so equipped: so they can add RPM.

Step 1: You have got the standard hose going from the headpipe to the stinger. Take note that most of the engine’s cooling water is run through this hose after cooling the engine and headpipe.

Step 2: When you cut the hose for the flow control valve installation, shorten it approximately one and a half to two inches (This is the length of the Jetworks flow control valve).

Step 3: Place the flow control valve between the hose ends with the arrow pointing toward the stinger. Tighten clamps. The valve is externally adjustable; you can turn the latter by hand without loosening the clamps.

Step 4: Normally you want to run at four and a half PSI. The valve is adjustable so you can get it down as low as half a PSI or up to 16?17 pounds of pressure. You seldom have to run anything over 8 PSI.

The water pressure in the cooling system is important because you have to take into consideration what is being bypassed. In other words, when would you run low PSI? Answer: If you are bypassing a lot of water. Triple pipe systems usually run two and a half PSI. One of the key things you want to remember is if you have a lot of water you’re bypassing, you need to have low pop?off on the valve. Remember, water always seeks the easiest path.

Step 5: In some applications of the flow control valve, you’ll run a separate dedicated cooling line to the exhaust only. In those particular situations, you can run higher pressures. The pictured boat was set up at seven and a half PSI. By adding the valve and controlling the bypass and restrictor diameters, the valve can be used for complete water flow or pressure management. This higher pressure can increase response further by making the water injection orifices and/or nozzles work quickly and more effectively. It doesn’t do you any good if your solenoid is on, but the water pressure is lower than the pressure inside the pipe.

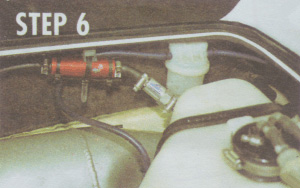

Step 6: The advantages of a flow control valve over a solenoid system? According to Jetworks, the increased rpm in the top end is something that cannot be obtained when using an electronic solenoid to control the amount of water going to the stinger. With a solenoid system, you’ve got more wiring, more connections, more moving parts that could go bad.

Why not increase rpm mechanically for less cost then the price of a solenoid itself? The flow control valve adds more water than the solenoid because the solenoid is limited to how much water it can flow, usually at 3/32 diameter orifice. In other words, the solenoid will not flow the amount of water needed in the top?end in order to increase the top?end speed.

So, with an installed flow control valve, you have added value and performance to your aftermarket pipe and, of course, your prized personal watercraft. And specifically, you will see some greater performance at the starting line as you wave bye?bye to the competition.”

Text by Jet Sports Magazine 1998